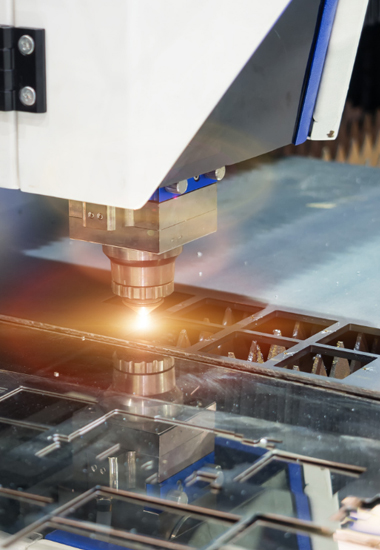

TUBES AND SHEET METAL LASER CUTTING

MDL offers its customers excellent quality services, thanks to decades of experience in the processing of tubular products and constant investment in the development of new processes and technologies. MDL’s laser cutting systems can process any material: iron, stainless steel, aluminum, brass, copper, duplex and Hardox®.

The service provided by MDL is precise, its quality excellent and the delivery always on time. For over thirty years MDL has been a reliable point of reference for its customers.

The in-depth skills of the MDL team in the field of laser cutting allow them to support and advise the customer in the realization of complex and ambitious projects.

The laser cutting system allows:

- The control and acceleration of the "booster" drilling process

- The separation, collection and palletizing downstream of unloading;

- The preservation of the integrity of the pieces also in the internal surface.

Find out more about our laser cutting systems:

THE ADVANTAGES OF

LASER CUTTING

Compared to other cutting techniques, laser cutting allows you to obtain a better result in terms of quality, time and cost. The resulting product is ready to be welded, painted, chromed, … or simply assembled.

WHY LASER CUTTING?

- Higer quality of the cut

- Extremely regular edges of the product

- Processing speed higher than other techniques

- It can be used on any material and with any thickness

- Considerably lower consumption of electric power